The progressive south aluminum truth-seeking, pragmatic and steady Development

Development record of fujian nanping aluminum co., LTD

Nanping aluminum is now one of the top ten aluminum extruders in China (ranking third in comprehensive strength). Aluminum industrial scale in the first place in the domestic same type enterprise, now has annual output of 75000 tons full aluminium industry chain (electrolytic aluminum - aluminum casting, aluminum - aluminum engineering), and is expanding to plate strip for the leading product, the annual output of 75000 tons of aluminum industry chain at the same time in yearly produces 100000 tons of aluminum plate with the chinalco (foil), fujian company. The technical equipment of the industrial chain is at the advanced level in the national industry and has obvious competitive advantages in aluminum profile production technology.

In the period of the fujian nanping aluminium co., LTD. (hereinafter referred to as "south" aluminum) production and operation in serious trouble, at the end of the south of the ninth five-year plan and aluminum table asset-liability ratio has reached 90%, business is struggling. After seven years of hard work, south aluminum achieved a steady development, in five aspects of significant changes. (a) from a smelting technology facing backward countries eliminated, the small enterprise, become a smelting, casting, aluminum industry chain among the forefront of group class aluminum co., LTD, the national top 10 aluminum production enterprises, comprehensive strength in the third) of the large state-owned aluminium company. (2) from an enterprise with a real annual loss of nearly 100 million yuan and a weak accumulation capacity, it has developed into a company with a real annual profit of 100 million yuan and a strong accumulation capacity. (3) from a single aluminum varieties, product sales are limited in southeast fujian and zhejiang, aluminum annual output 20000 tons, product sales income is 20000 yuan (south of aluminium and its the cords holding enterprises amounted to 1.2 billion yuan) of the enterprise, Developed into aluminum cover almost all series of varieties, product sales market covering the major coastal cities in China and exported to more than 30 countries and regions, aluminum annual output 64000 tons, product sales income is 64000 yuan (5.415 billion yuan) as a whole, profits of 102 million yuan, tax 110 million yuan, 10029, extract, extract depreciation wages 100 million yuan (including the Labour cost) of the company. The per capita income of employees has been increasing year by year, and the social contribution has been outstanding, especially in 2007, when the sales income, profits and taxes and other major economic indicators all hit the best level in history. (4) from a patented product is zero, few new products, technology development ability is weak, become 317 national patent products, 3 national key new products, has China's brand-name products, China famous trademark, a CNAS certificate of national laboratory and the provincial technology center and the main drafting aluminum building insulation material national standards of the company. (5) from a backward smelting process workshop environment pollution, poor living conditions of the enterprise employees, become a advanced technology of clean production enterprises, with standard indoor swimming pool, gymnasium and staff club and nearly thousand sets of new employee housing, beautify the environment of the province, the only one enterprise to create national green community.

This is a series of change and progress, thanks to provincial leadership and the concern and support of relevant departments, thanks to the south aluminum, seeking long-term steady development of the scientific outlook on development, thanks to the efforts of the practice, practical work style, embodies the shareholders, employees and enterprise harmonious unification relations. Facts have proved that large state-owned enterprises can do well.

The steady development of south aluminium has mainly taken five measures.

First, we are committed to technological transformation and building a complete aluminum industry chain

Since 2000, the market competition of aluminum profiles has been extremely fierce. The price war of aluminum profiles has been fierce. The electrolytic aluminum industry has become a key target of state control.

The annual increase of the electricity price of electrolytic aluminum has reached nearly 100 million yuan every year. The price of raw material alumina increases year by year, and the relationship between aluminum ingot and alumina is seriously distorted. Under the condition of the market, the south aluminum multiple organization staff to carry out the development of south aluminum big discussion, careful analysis adverse environment the development direction of south aluminum and core competitiveness, to formulate the development planning and detailed measures, clear aluminum industry chain must be made through this article, to build a complete aluminium industry chain as the main target, enhance the core competition of the south of aluminium. In recent years, south aluminum investment of more than 10, one hundred million yuan annual output of 73000 tons of environmental protection and energy saving electrolytic aluminum, annual output of fluorine carbon aluminum 30 square meters, annual output of 50000 tons of aluminum casting, annual output of 40000 tons of pre-baked anode, annual output of 20000 tons of aluminum and so on more than ten projects of technological transformation, technological transformation projects to stimulate enterprises to develop and improve the level of technical equipment, adjustment of product structure and enhance competitiveness. Among them, two projects have achieved remarkable results: one is the transformation of electrolytic aluminum technology. Before 2001, nal was a 60KA self-baking electrolytic cell with a scale of only 30,000 tons. Its technology was backward and the environment was polluted. In 2001, the production and operation of south aluminum was still very difficult. It was impossible to carry out technical transformation through new bank financing. Through efforts to win the support and consent of the province, nal decided to invest 400 million yuan in the environmental protection and energy conservation of 240KA large scale pre-baked electrolytic aluminum technology transformation.

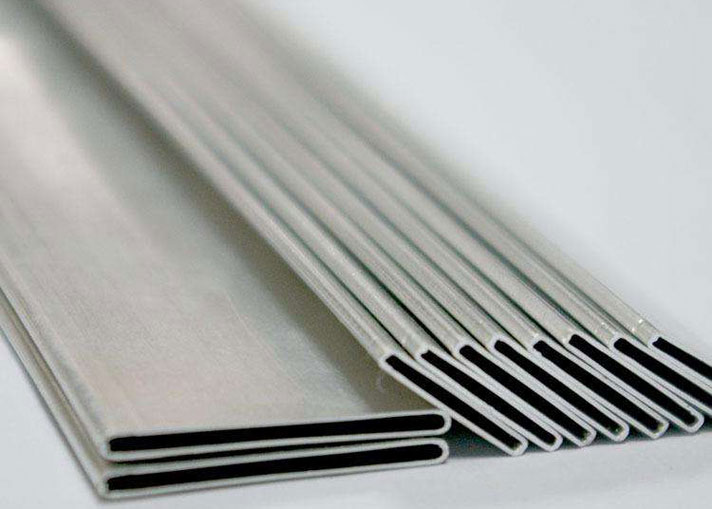

The project, measures in place, the effect is obvious, no matter in terms of speed of construction has tons of aluminum investment saving, all the best level at that time, the domestic industry to achieve the production and transformation efficiency from the target, for south aluminum improve annual output of 75000 tons of aluminum industrial chain laid a foundation. The project won the provincial government "2003 provincial key construction project award" and was awarded the "fifteenth five-year" technical renovation project by the provincial economic and trade commission. Second, the technical transformation of aluminum profiles. In 2004, after completing the technical reform of electrolytic aluminum, nanal invested another 300 million yuan to expand the annual output of 20,000 tons of aluminum profiles. The project started construction in March 2004 and was completed in 2006, which created favorable conditions for the expansion of the business scale of the company. The addition of 40 mn double-action extruder, 38 mn forward extrusion machine, aluminum vertical quenching line, mold machining center equipment greatly improve the technical equipment level of the south aluminum, make the whole industry chain technology and equipment are all reach the advanced level of the industry.

The technical transformation project of aluminum profiles was well timed, the technology and technology were selected appropriately, and the input and output effects were obvious. In just a few years, south aluminum has won the provincial government to provincial key construction projects for two consecutive provincial recognition of the highest honor, few enterprises in the province. Through a series of renovation and expansion, the south has formed annual output of 75000 tons full aluminium industry chain (electrolytic aluminum - aluminum casting, aluminum), scale of industry chain in the forefront of the aluminum companies in the group, in 760 aluminum production companies in the country ranks the top 10, become the only state-owned enterprises in the aluminum top ten. The formation of an annual aluminum industry chain with an annual output of 75,000 tons has strengthened the competitiveness and risk resistance of south aluminum, with obvious scale and efficiency, laying a good foundation for its excellence and further development.

Second, adhere to independent innovation and continue to promote scientific and technological progress

Along with the change of the market, people also increasing varieties and quality requirements for aluminum, aluminum building great changes have taken place in the market demand, the original 90 series and single color aluminum oxidation coloring gradually eliminated by the market. In the face of this change, south aluminum timely took effective measures, market-oriented, committed to the development of new types of aluminum profiles, highlight sound insulation energy-saving aluminum doors and Windows and new products of industrial profiles.

Has successfully developed the 56 series and 728 series and so on sound insulation energy-saving high-grade aluminum Windows and doors, 60 series new doors, railing on decorative profiles, containers, radiator, industrial aluminum products, such as ladder, trunk, colored frosting electrophoresis, wood grain transfer printing, fluorine carbon spraying and other new products.

Independent development of the new series of products such as 868, EU, and against the south and in hot summer and warm winter area development DW568 and DL868 series and so on economic energy-saving insulation window, its price is competitive than similar varieties in the market at present, a solid construction aluminum in the high-end market. Compared with 2000, fundamental changes have taken place in the variety of aluminum structure, old varieties series no longer manufacture, by the southern aluminum drafting national standards of energy-saving aluminous profile has gradually become the mainstream of the market consumption.

While focusing on product innovation, nal has been working hard on technical innovation. The company has established a technological innovation and development mechanism. Director of the professional engineer according to the company to saving energy and reducing consumption, improve business efficiency and improve technology, etc, put forward the scientific and technological innovation projects, after review included in the plan, select the project, to organize and implement, head of the end of the year, according to project implementation, give corresponding reward. Through scientific and technological development and innovation, we have also achieved good results. Including "240" ka pre-baked electrolytic process optimization project not only improved the original tank control system concentration control and pole changing, the aluminum system parameter Settings, and improved the stability of slot, achieve the goal of the electrolytic aluminium production efficiency. "Oil and gas lubrication mold development and phi phi 165 mm 305 mm oil-gas lubrication casting system localization design" project not only in the localization of advanced technology in the domestic leading level, and saved more equipment investment. The successful design and development of large-size oil and gas lubrication casting platform has made the south aluminum casting level advanced in the industry. Scientific and technological development and innovation projects, such as technology and technology of large aluminum extruder and comprehensive energy-saving technology of industrial furnace, have achieved phased results. The "6.18" project jointly developed with guangzhou fangce co., ltd. is the largest management information system of domestic aluminum profile production enterprises. After the completion of this management information system, the working efficiency and management efficiency of south aluminum will be significantly improved. Work through the development of science and technology development and innovation, not only improve the south aluminum product structure, promote technological progress, sustaining the development, but also improve the technical level of the scientific and technological personnel, arouse the enthusiasm of the staff of science and technology innovation and creativity, exercise science and technology personnel team. Since 2005, the company has invested more than 15 million yuan in scientific and technological development and innovation projects, directly and indirectly generating economic benefits of about 25 million yuan.

So far, south of aluminum has been approved by the state intellectual property office of 317 aluminum appearance design and utility model patents, patent filing in the same industry at home and the quantity of the certification are ranked first, was rated "fujian province, the first patent pilot work advanced unit". Three products have been listed as national key new products, and seven products have been listed as provincial key new products. Is given priority to the drafting of GB5237.6 the national standard of the journal building aluminum shaped heat insulation material, for the most market prospects in national aluminum six standard standard, was named "2005 China nonferrous metals industry science and technology second prize". Participated in drafting fujian aluminum alloy building doors and Windows engineering technical regulations. South aluminum is one of the four national GB5237 "aluminum alloy building profiles" test and development bases, with a provincial technical center, central laboratory CNAS certificate for national laboratory. "South aluminum independent innovation results significantly" in the list of "2006 nanping top ten news."3. Change marketing concepts and actively explore domestic and foreign markets

Since entering this century, aluminum market supply as the main characteristics of architectural aluminum market from the traditional "retail, wholesale sales model to piece development engineering orders," seek meters pot "become the main feature of southern aluminum extrusions sales, is facing a price war, fierce competition in the aluminum market. In order to quickly adapt to this market change, nac has strengthened its sales team construction and strengthened its ability to undertake orders and services by strengthening management and assessment. By changing the concept of marketing, from the "pin" into "promotion", from "single product sales" to "combination product sales", from "passive" to "active orders", from "single pricing model" to "aluminum ingots + processing fee pricing, large single pricing, aging pricing, risk pricing", the risk of stock market effectively, increase the order quantity. Through active participation in can get major project bidding and play south aluminum product innovation, quality and "fujian aluminum" brand advantage, insist on quality, develop domestic aluminum main market. In seven years, the enterprise overseas offices from fuzhou, xiamen and development in 2000 in Beijing, Shanghai, guangdong, hangzhou, suzhou, Qingdao, jinan, nanjing and other 23 offices, establish an effective sales network, aluminum scale for three times. At the same time, great progress has been made in undertaking large-scale landmark building projects in China. If has to undertake the macau new yaohan, China national grand theater, the national stadium, the capital museum, Beijing TV center, Shanghai fudan international exchange center, Shanghai F1 circuit, hangzhou China academy of art, hangzhou grand theatre, ningbo international conference and exhibition center of jinan, shandong yantai gymnasiums, this text penglai zijin hill international golf club, Qingdao, wuhan new world center, suzhou mold crown international sports center, futian, shenzhen, hainan boao BBS convention and exhibition center, dalian fire command center, the people's bank of changchun, heilongjiang electric power building fit-out large landmark buildings such as aluminum supply contract, Improved the "fujian aluminum" aluminum profile visibility.

South aluminum look also concentrating on the international market, starting from the basic aluminum exports in 2003 to zero, after three years hard work, close to 2006 aluminum exports of 2006 tons, products are exported to the United States, Germany, France and so on more than 30 countries and regions. While developing and popularizing various energy-saving aluminum profile doors and Windows series, actively developing various industrial aluminum profiles, the proportion of industrial aluminum profiles also increases year by year. In 2007, the production and sales volume of south aluminum profiles achieved a new leap.

Deepening reform and strengthening management, and establishing a modern enterprise system

In 2001, south aluminium combines debt to turn into a limited liability company. After years of capital increase and share, south aluminum existing asset-liability ratio is about 52%, capital of 853.88 million yuan, including provincial metallurgical (holding) co., LTD. 50.98%, huarong asset management company 12.08% 36.94%, Orient asset management company, enterprise assets and liabilities structure remains stable. South aluminium undertakes standardized management according to the requirement of modern enterprise system. In recent years, we have further deepened reform and asset restructuring and achieved remarkable results. First, we streamlined the internal organization, eliminated the building system of the workshop, and realized the flat management. Second, the hospital and other non-operating assets were stripped off and a property company was established to complete the separation of the main and auxiliary enterprises.

Third, we have implemented the annual performance evaluation system for recruiting senior and middle-level cadres, built a fair competition platform, and properly solved the problem of cadre ability to go up and down. Fourth, it absorbed the merger and reorganization of the new bank of China, dealt with the problems left over from history in a prudent way, and regulated the trading behaviors of the internal affiliated enterprises. Fifth, private capital was introduced to establish the company, the carbon anode production line was built, and the aluminum industry chain was extended. Six is to solve the south aluminum foreign investment "three red fujian company" problems left over by history, complete the absorption merger restructuring south aluminum plate strip, build the south aluminum extrusions, aluminum strip of two business management system. Seventh, we successfully introduced chinalco and completed the asset reorganization of ruimin aluminum plate and belt co., ltd. and achieved a win-win situation.

Through a series of reform measures, south aluminum straightened the property right relations, established the modern enterprise system, and added vitality to the development. During the tenth five-year plan period, labor productivity per capita more than doubled.

In 2004, the introduction of aluminum corporation of China southern aluminium corporation (nal), the completion of the reorganization of assets of the ruimin aluminum plate zone and the establishment of the ruimin company were one of the important measures for the success of enterprise reform in recent years. The asset restructuring is complex and complex