Energy conservation and emissions reduction for enterprise scientific development - fujian nanping aluminium co., LTD., fujian nanping aluminium co., LTD. (hereinafter referred to as "nanping aluminium") formerly known as fujian nanping aluminium factory, founded in 1958, is a large state-owned enterprises. Company registered capital of 1.0287 billion yuan, has two branches, 3 holding companies, three share company, have 4740 employees, the south of aluminium and its and holding companies in product sales income over 5 billion yuan (excluding tax). Nanping aluminum product brand enjoys high reputation and reputation in the market. The "fujian aluminium" trademark is "China famous trademark", the leading product "fujian aluminium" section material is "China famous brand", "the national quality exemption inspection product". The main products are various specifications and series of aluminum profiles, alloy rods, sheet (foil) materials, cast and rolled coil materials, fluorocarbon aluminum veneer, aluminum finished doors and Windows, etc. "Fujian aluminum" series products such as energy-saving thermal insulation aluminum building profiles have won the national non-ferrous metal product physical quality "gold cup award". Enterprises carrying out the advanced quality management concept and system, is the earliest ISO9001 quality system and aluminum alloy construction material products qualified double certification of enterprises, has passed the quality, environment, occupational health and safety management system (QEO) and the national measurement management system certification.

Since entering this century, nanping aluminium adhere to scientific and technological innovation, science and technology enterprise, make enterprise get better faster development: from a smelting technology facing backward countries eliminated, the small enterprise, become a smelting, casting, aluminum industrial chain combined with one of the best companies in the trade, the national top 10 aluminum production enterprises, comprehensive strength in the third) of the large state-owned aluminium company; From zero patents, science and technology innovation ability is weak, become with aluminum extrusions look and more than 320 utility model patents, patent filing in domestic aluminum industry and the quantity of the certification are ranked the first, there are four national key new products, mainly drafted GB5237.6 national standard architectural aluminum shaped insulating material, is the national GB5237 aluminum alloy construction profiles "four national standard test base, one of the central laboratory by CNAS certificate, for the national high and new technology enterprise, national innovative pilot enterprises, have decided that a country enterprise technology. After years of efforts, nanping aluminium has from a smelting environment more pollution, poor living conditions of the enterprise employees, develop clean production, with standard indoor swimming pool, gymnasium and staff club and newly built nearly thousand staff housing, beautify the province only one enterprise independent construction of national green communities. This series of changes and progress, thanks to the nanping aluminum industry adhere to the "steady development, long-term" business philosophy; Thanks to the vigorous development of recycling economy, energy saving, consumption reduction and emission reduction of nanping aluminum industry, the company has adopted the growth mode of new industrialization path of sustainable development. First, it is the focus of energy conservation and emission reduction of nanping aluminum industry to change the growth mode and promote the upgrading and transformation of the industrial chain. Through technical transformation, it is one of the most important measures to build a complete aluminum industry chain. As a typical large enterprise with high energy consumption and resource utilization in fujian province, nanping aluminum industry is a large energy consuming enterprise in fujian province. In recent years, nanping aluminum investment of more than 10, one hundred million yuan for environmental protection and energy saving of 240 ka pre-baked slot aluminium, annual output of fluorine carbon aluminum 30 square meters, annual output of 50000 tons of aluminum casting, the annual output of 40000 tons of pre-baked anode, annual output of 20000 tons of aluminum, annual output of 12000 tons of industrial composite aluminum, annual output of 50000 tons of plate and strip and so on more than ten projects of technological transformation, to project technical reform to realize the change of the pattern of economic growth.

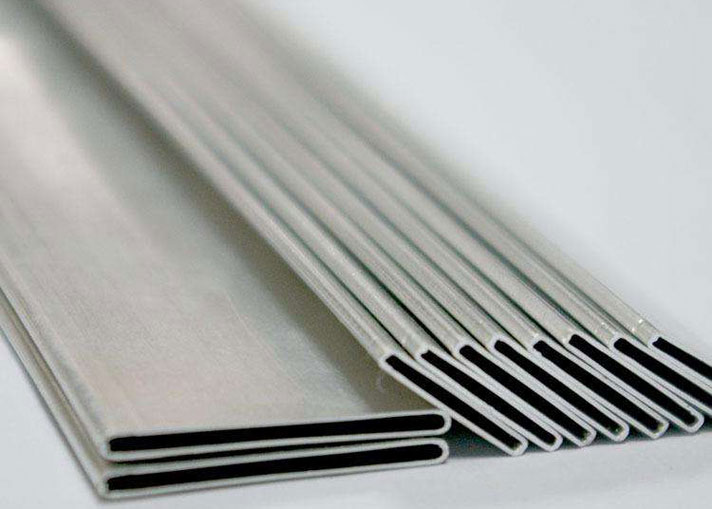

Two of these projects have been successful. First, the technical transformation of electrolytic aluminium. Before 2001, nanping aluminium electrolytic aluminium was a 60KA self-baking electrolytic cell with a scale of only 30,000 tons. The technology was backward and the environment was seriously polluted. Since 2001, nanping aluminium overcome enterprise funds, bank financing, such as all kinds of difficulties, decisive investment for environmental protection and energy saving 240 ka large pre-baked aluminium technology reform, every eliminated for enterprise services lag of 32 years since the electrolytic tank. In terms of both the construction speed and investment saving per ton of aluminum, this project is at the best level of its domestic counterparts at that time, laying a foundation for nanping aluminum industry chain to build an annual output of 150,000 tons of aluminum. The project won the fujian provincial government "2003 provincial key construction project prize", "15" technological transformation by the provincial economic and trade commission as outstanding projects, nanping aluminum became a national environmental protection bureau announced the first batch of electrolytic aluminium enterprises comply with environmental regulations. South aluminum electrolytic aluminum project put into production, the development of science and technology innovation and management innovation, combined with the "11th five-year" plan for energy conservation and emissions reduction, will guarantee the life of electrolyzer, reduce electrolytic aluminum power consumption as the main direction. First of all, it is necessary to strengthen the fine operation and management in the field, improve the technological level of the electrolytic cell process regulation, and improve the operation stability of the electrolytic cell. Secondly, by optimizing the technological conditions, the electrolytic cell voltage is continuously reduced. Thirdly, the anode effect coefficient is reduced by strengthening the management and assessment of anode effect. At the same time, the supervision and management of anode quality, anode assembly quality, feeding and other processes are constantly strengthened. Second, the technical transformation of aluminum profiles. In 2004, after completing the technical reform of electrolytic aluminum, nanping aluminum industry invested more than 300 million yuan in aluminum profile series projects. The project started construction in March 2004 and was completed in 2006, creating favorable conditions for the expansion of the operation scale of nanping aluminum industry. New 55 mn extruder, 40 mn double-action extruder, 38 mn is 25 mn extrusion machine, 16 mn series aluminum extrusion machine, powder spraying vertical line, vertical quenching line, mold machining center equipment, greatly increasing nanping aluminum industry technology and equipment level, make the whole industry chain technology and equipment are all reach the advanced level of the industry. Due to project timing, choose appropriate technical process, input and output effect is obvious, nanping aluminium extrusions technical again won the fujian provincial government "2006 provincial key construction project prize". In just a few years, nanping aluminum has won the provincial government's highest recognition of provincial key construction projects for two consecutive times. After a series of expansion and transformation, nanping aluminium has formed annual output of 150000 tons full aluminium industry chain (aluminium/aluminium casting (aluminium roll) - aluminum (aluminum), scale of industry chain in the forefront of the aluminum companies in the group, unique among China's aluminum top state-owned enterprises. Through technical transformation, not only eliminate the high energy consumption, the craft is the backward production capacity, but also in the same factory for electrolytic aluminum, aluminum casting (pad), aluminum processing industry chain upstream and downstream capacity of collaborative development steadily, and greatly shortens the distance between upstream and downstream industry chain transfer order logistics process, saving energy consumption of the turn sequence logistics; The process of aluminum casting (rolling) is realized without dropping the electrolytic aluminum water directly into the process of aluminum casting (rolling), and the energy consumption of aluminum ingot remelting is saved.

Nanping aluminium current aluminum goods material processing capacity has reached more than 150000 tons/year, due to the use of production of electrolytic aluminum, aluminum water directly alloy round ingot (cast-rolling strip), greatly reducing the loss of aluminum ingot and reduce energy consumption, produce about 400-400 yuan per ton benefit, industrial chain in the direct economic benefit of 60 million yuan. Second, based on scientific development, energy conservation and emission reduction measures, and the establishment of a long-term mechanism for resource conservation, must be based on scientific development and comprehensive governance. Nanping aluminum industry energy conservation and emission reduction measures, promote the good and fast development of enterprises. Electrolytic aluminium production, after years of careful operation and management, while the nanping aluminum electrolytic aluminum projects in the domestic scale is not big, but the main technical economic indicators remain advanced, in the same groove of the nation's main technical and economic indexes are among the best in electrolytic aluminium enterprises, in 103 aluminium companies in the country, electrolytic aluminium ac power consumption dropped to 13000 KWH/tons; Current efficiency 94% above, at the domestic advanced level. Compared with the self-baking electrolytic cell before transformation, the electric saving of aluminum over 2500 KWH is very outstanding. Aluminum profile, according to the national building energy conservation development strategy requirements, energy-saving doors and Windows application is imperative. Therefore, nanping aluminium timely developed has certain life cycle and independent patent technology, high-grade energy-saving Windows and doors series, instead of traditional Windows and doors, ensure that company always have multiple Windows system as a market leading products series. The L63 series single slide sliding window developed and produced by nanping aluminum industry is the first in China. "Q65 dry glass curtain wall system" project won the national patent, compared with the traditional glass curtain wall, profile use saves about 10%, was awarded the second session of worker innovation across the Taiwan straits, whose comprehensive performance index has reached the domestic leading level. Many series of independently developed Windows, such as D50 series heat insulation horizontal open Windows and D728 series heat insulation push and pull Windows, have passed the certification of national building energy saving products (CQC). According to the development strategy of national building energy conservation, the application of energy-saving Windows and doors is imperative. Therefore, nanping aluminium timely developed has certain life cycle and independent patent technology, high-grade energy-saving Windows and doors series, instead of traditional Windows and doors, ensure that company always have multiple Windows system as a market leading products series. The L63 series single slide sliding window developed and produced by nanping aluminum industry is the first in China. "Q65 dry glass curtain wall system" project won the national patent, compared with the traditional glass curtain wall, profile use saves about 10%, was awarded the second session of worker innovation across the Taiwan straits, whose comprehensive performance index has reached the domestic leading level. The independently developed D50 series heat insulation horizontal open Windows and D728 series heat insulation push and pull Windows have passed the national building energy saving products (CQC) certification. While committed to energy conservation, nanping aluminum has made great efforts to reduce emissions. For a long time, nanping aluminum industry has always attached great importance to environmental protection work and regarded environmental protection and social benefits as the source of the company's sustainable development. Company set up to the general manager responsibility system as the core of environmental management system, and determines the walk ", relying on technological progress, prevention and control of parallel implementation of cleaner production "way, not only in the process of production the minimum cuts in the production of" three wastes ", at the same time to achieve maximize the use of pollutants, the environmental benefit, economic good benefits have been achieved. In order to effectively control the environmental pollution of electrolytic aluminum production, from 2001 to 2003, nanping aluminum invested 380 million yuan in the construction of environmental protection energy-saving electrolytic aluminum technology reform project, of which more than 30 million yuan was invested in environmental protection facilities. Practice has proved that aluminium technology reform environmental protection effect is obvious, in August 2004, the fujian provincial environmental monitoring center monitoring, the indicators are discharging standard, implements the production reducing the pollution, greatly improved the south nanping aluminium, jade screen park and urban atmospheric environment quality condition.

With the continuous expansion of company in recent years, aluminum production, the wastewater quantity increased, the original oxidation coloring wastewater treatment capacity can not meet the needs of production, aluminum has invested more than 2000 2000 yuan to build the concentration of the two sewage treatment station, the company all production wastewater discharging standard network centralized processing, after put into operation, the processing capacity of 250 tons/hour. According to the monitoring station of nanping city, the waste water has reached the intermediate level of the national gb8978-96 comprehensive discharge standard, and the total amount of sewage discharge has significantly decreased, effectively reducing the water environmental pollution load of the minjiang river. The aluminum waste residue produced in the process of wastewater treatment has been comprehensively recycled. Nanping aluminium invested more than 100 100 yuan, successively in the casting roll mix build two aluminum slag recycling machine, hot slag smelting furnace rake out after blender mixing, the effective recycling residual metal, and ready to invest millions of dollars this year, build the grinding production line, then the residue after mixing grinding, and then into the cell of smelting, realization of electrolytic aluminum - aluminum casting (roll) - production processing of slag discharge cycle. In order to reduce pollutant emissions, three existing coal-fired boilers with a total capacity of 16 tons have been dismantled, and 1.2 million yuan has been invested to build three 1.5-ton fuel boilers. The heat efficiency of 1.5t oil-fired steam boiler is 5-11 percentage points higher than the standard specifications, and the energy saving effect is significant. The blackness, noise, smoke emission concentration, sulfur dioxide emission concentration and other environmental indicators of flue gas all meet the national standards. So2 emissions (from 48 tons/year to 4 tons/year) decreased significantly, near the factory, living quarters and atmospheric environment improved significantly, and has obvious social benefits and environmental benefits. Third, beautify the environment, build national green community is committed to building south aluminum "" green environmental protection idea, build up related to every employee life" green home ", nanping aluminium become a beautiful scenery since 2001, nanping aluminium successively invested one hundred million yuan for the factory, the living quarters of greening, landscaping, and comprehensive hardware facilities construction. Campus, community, strictly implement housekeeping management, and beautify the synchronization, the company beautiful environment clean and tidy, greening, community coverage rate of 37%, was awarded the "provincial garden-like enterprise" title. In order to build nanping aluminum into a garden-style civilized community, the company has formulated a plan, combined with a series of technical transformation such as electrolytic aluminum, and increased the construction of the company garden-style civilized community. In order to improve the housing conditions of the employees, the company has completed four fund-raising and built a number of capital houses and affordable housing, which has fundamentally improved the living environment and conditions of employees in the community. Southern aluminum also build supporting the community hall gate, stadiums, clubs, employees, indoor standard swimming pool, college student apartments and other facilities, in recent years, nanping aluminium enclosure transformation with a total construction area of 110000 square meters, fixed assets investment of 100 million yuan, more than 960 sets of new worker housing (most for high-rise elevator housing), with a total area of more than 105000 square meters, equivalent to the south factory since aluminum construction area combined. At the same time, the supporting construction and greening beautification, the community environment looks brand-new.

On June 5, 2005, it was awarded "national green community" by the state environmental protection bureau, and became the only state-level green community established by enterprises in fujian province. Aluminum in recent years, the south also won the national spiritual civilization create work advanced unit, the national May 1 labor certificates, national advanced unit for equipment management, the provincial advanced enterprise of energy conservation, province enterprise culture construction demonstration units, the best credit enterprise "and other honors. Now, entering nanping aluminum industry, a fresh green sense of the coming, the streets on both sides of the community trees lush, birds singing; Under the blue sky, the white and blue plant is hidden in the swaying flowers and branches, imposing. From a distance, a large and green modern enterprise is presented in front of your eyes. The beautiful environment edifies people's sentiment and enriches people's life. The old smelting company has become a veritable garden factory. In the survey of employees' and community residents' satisfaction conducted by enterprises in the past five years, employees' and community residents' satisfaction with the two civilized construction measures of nanping aluminum industry reached more than 95%. Over the years, thanks to scientific progress, technological transformation, product innovation and management innovation, nanping aluminum industry has achieved remarkable results in energy conservation and emission reduction. As the global resource scarcity, countries more and more high to the requirement of emissions, we are a long way to go, energy saving and emission reduction as premier wen jiabao in his government work report points out, this year is to complete the "11th five-year plan", a obligatory targets for energy conservation and emissions reduction, it is important to strengthen the sense of urgency and intensify efforts to strive to make greater achievements.